- 联 系 人|董家兴

- 联系地址|江苏-淮安

- 查看详情 >

生产销售 快速反应蒸纱机 吉日签定

我公司生产的快速反应纱线真空给湿蒸纱机,能提供一个极具成本效益的方法来提高纱线质量品质。该机可对纱线进行热定型.给湿处理,均匀渗透,有快速反应蒸纱增加棉纱重量的功能,增重达1.7%-…3%,增加毛纱重量多达2.4%--4%。

J40s管纱,蒸纱前后毛羽变化情况见表

. the quality to be stable, the temperature, the humidity accuracy control enables each production lot to obtain same level processing. the 3. investment recoupment period is short, is lower than the import equipment investment cost, is more obvious than the home equipment energy conservation.

. non-impact processing, non-condensation spot.

. both can the attemperation, and can adjust the humidity.

. suits processes the car, to transport the yarn which the gauze box loads.

. may process each kind natural and the synthesis staple fiber yarn, mixes reels thread. Third, yarn heat setting

. model yarn steaming craft step the vacuum - - preheating - - adds the wet - - heat preservation. The constant temperature - - vacuum temperature decrease - - finished

. unique preheating system

in the yarn steaming process, on the yarn water drop spot will be the common problem, the water drop spot will cause dyeing as well as latter working procedure other questions, therefore, the yarn steaming preheating craft was the absolutely necessary, particularly wool yarn. .Yarn thermal fixation the each production working procedure (reels thread, twisting, weaving ......) to be able to cause the gauze and the textile fiber tensity effect, the tensity function can cause the gauze tangle. After the tensity and the tangle can give, a working procedure brings the question, but the artificial fiber mol structure s stress relaxation is had the textile fiber the contraction, therefore, the astute machinery produces the yarn steaming machine has brought the best choice for the yarn production. the research indicated that the following type s yarn must use the yarn steaming to carry on the relaxation and the setting: The cotton yarn, the wool yarn, the polyester-cotton blend reel thread, the polyester fiber gauze, Bao Xinsha (ammonia black silk ribbon), the tailoring line, the man-made staple fiber yarn, the acrylic fiber silk to tie, the mesh knitted fabric (crimped fibre).

each raw material needs the specific processing craft to achieve the ideal effect,

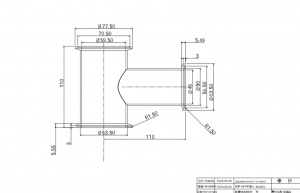

工艺分类

工艺分类